Min.Order FOB Price

2 set 70.00-112.00 dollar / set

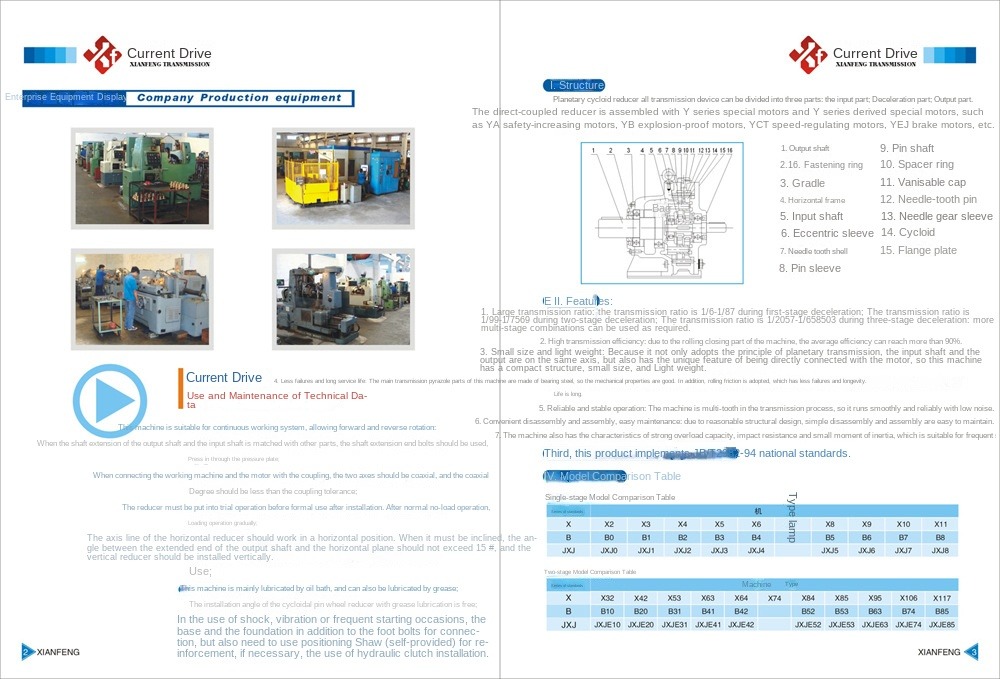

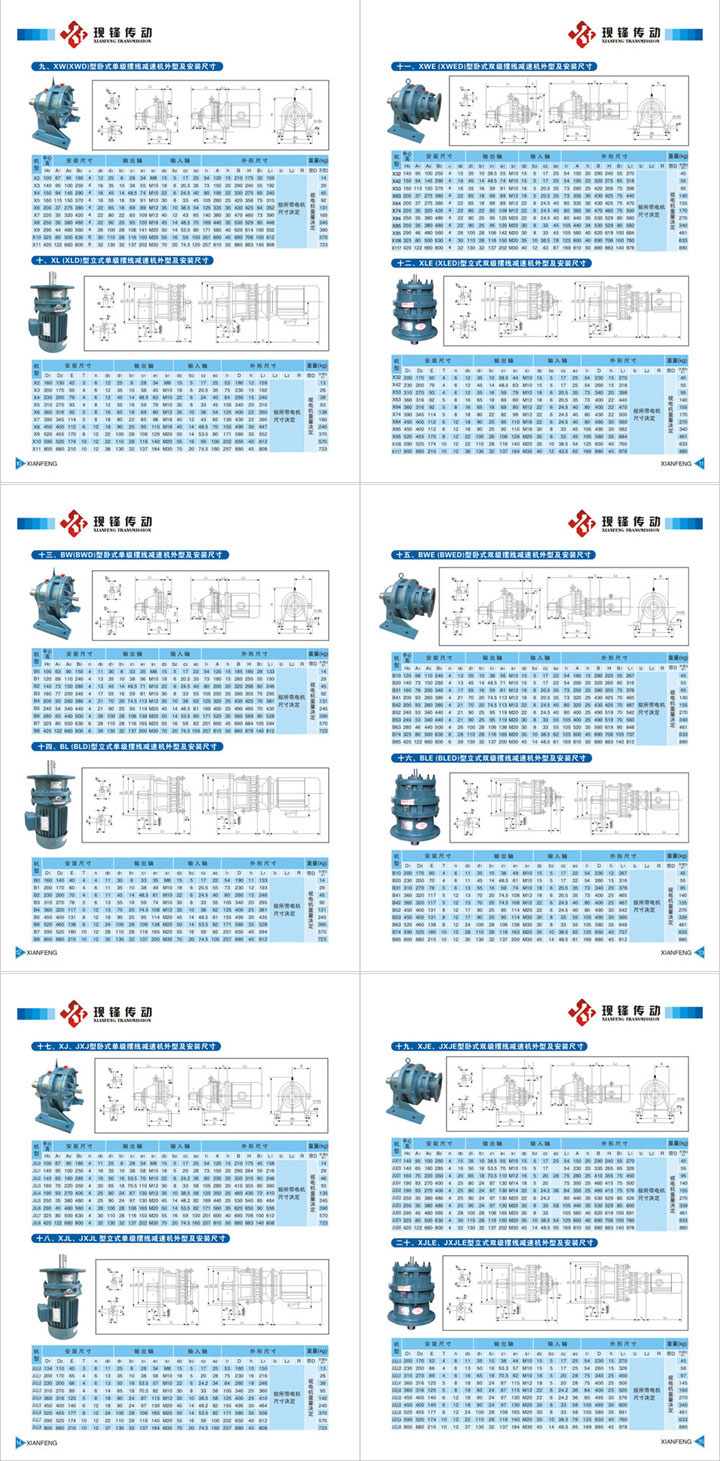

1. use and maintenance: 1. This machine is suitable for continuous working system, allowing forward and reverse rotation. When the shaft extension of the output shaft and the input shaft is matched with other parts, the shaft extension end bolt should be used to press in through the pressure plate. 2. When connecting the working machine and the motor with the coupling, the two axes should be coaxial, and the coaxiality should be less than the coupling tolerance. 3. After the reducer is installed, it must be put into trial operation before formal use. After the no-load operation is normal, it will be gradually loaded and operated. 4, horizontal reducer axis should be in a horizontal position to work, must have tilt, the output shaft extension end down and horizontal clamp should not exceed 15 ℃, vertical reducer should be installed vertically. 5. The machine is mainly lubricated by oil bath, and can also be lubricated by grease. The installation angle of the cycloidal pin wheel reducer lubricated by grease is free. 6. In the use of shock, vibration or frequent starting, the base and the foundation need to be reinforced with positioning shaw (self-provided) in addition to connecting with foot bolts, and hydraulic clutch installation is selected if necessary. Features of 2. cycloid reducer: 1. Large transmission ratio: the transmission ratio is 1/6-1/87 during first-stage deceleration; The transmission ratio is 1/99-1/7569 during two-stage deceleration; The transmission ratio is 1/2057-1/658503 during three-stage deceleration; More multi-stage combinations can be used as required. 2. High transmission efficiency: As the meshing part of the machine uses rolling meshing, the average efficiency can reach more than 90%. 3, reliable and stable operation: the machine transmission process for multi-tooth meshing, so the operation is stable and reliable, low noise. 4. Small size and light weight: Because it not only adopts the principle of planetary transmission, the input shaft and the output shaft are on the same nail axis, but also has the unique feature of being directly connected with the motor, so this machine has a compact structure, small size, The characteristics of light weight. 5, less failure, long life: the machine main transmission meshing parts using bearing steel manufacturing, so good mechanical properties, good wear resistance, plus the use of rolling friction, less failure, long life. 6. Convenient disassembly and assembly, easy maintenance: due to reasonable structural design, simple disassembly and assembly are easy to maintain. 3. uses: Cycloidal pin gear reducer adopts the principle of cycloid pin gear meshing and planetary transmission, so it is usually called, planetary cycloid pin gear reducer can be widely used in petroleum, environmental protection, chemical industry, cement, transportation, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, power generation and other industries, as a driving or deceleration device. Its unique smooth structure can replace ordinary cylindrical gear reducer and worm gear reducer in many cases. Therefore, planetary cycloid reducer is widely used in various industries and fields, and is generally welcomed by the majority of users. 4. conditions of use: 1, cycloid pin wheel reducer allows the use of continuous working system, while allowing positive and negative two directions of operation. 2. The rated speed of the input shaft is 1500 r/min. When the input power is greater than 18.5 kW, it is recommended to use a 960 r/min 6-pole motor. 3. The working position of the horizontal installation of the cycloid reducer is the horizontal position. The maximum horizontal tilt angle during installation is generally less than 15 °. Other measures should be taken to ensure adequate lubrication and prevent oil leakage when it exceeds 15 °. 4. The output shaft of the cycloid reducer cannot be subjected to large axial force and radial force, and other measures must be taken when there is a large axial force and radial force. 5. cycloid reducer structure model representation: 1, B series cycloid reducer BW foot plate type horizontal mounted biaxial cycloid pin wheel reducer BL flange type vertical mounted biaxial cycloidal pinwheel reducer BWY Foot Plate Type Sleeping Special Motor Direct-connected Cycloidal Pinwheel Reducer BLY flange type vertical mounting special motor direct connection type cycloidal pinwheel reducer BWD Foot Plate Type Sleeping Ordinary Motor Direct-connected Cycloid Pinwheel Reducer BLD flange type vertical mounting ordinary motor direct connection type cycloidal pinwheel reducer BWED double-stage foot plate type horizontal mounting ordinary motor direct-connected cycloid pin wheel reducer BLED double-stage flange type vertical mounting special motor direct-connected cycloidal pinwheel reducer 2. X series cycloid reducer XW foot plate type horizontal mounted biaxial cycloid pin wheel reducer XL Flange-type vertical-mounted biaxial cycloidal pinwheel reducer XWY Foot Plate Type Sleeping Special Motor Direct-connected Cycloidal Pinwheel Reducer XLY flange type vertical mounting special motor direct connection type cycloidal pin wheel reducer XWD foot plate type horizontal mounting ordinary motor direct connection type cycloidal pinwheel reducer XLD flange type vertical mounting ordinary motor direct connection type cycloidal pinwheel reducer XWED double-stage foot plate type horizontal mounting ordinary motor direct-connected cycloid pin wheel reducer XLED two-stage flange vertical mounted ordinary motor direct-connected cycloidal pinwheel reducer 6. type and type of cycloid reducer: B series single-stage models are: B0 1 2 3 4 5 6 7 8 9/ B 120 150 180 220 270 330 390 450 550 650 /B12 15 18 22 27 33 39 45 55 65 X series single-stage models are: X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 Single-stage reduction ratios are: 7 9 11 17 23 25 29 35 43 59 71 87 B series two-stage models are: B10 20 21 30 31 41 42 52 53 63 74 84 85 95 /B1512 1812 1815 2212 2215 2715 2718 3318 3322 3922 4527 5533 6533 X-series dual-stage models are: X32 42 43 52 53 63 64 74 84 85 95 106 117 118 The two-stage reduction ratio is 121 187 253 289 385 473 595 731 841 1003 1225 1505 1849 2065 2537 3481 4189 5133 7569 Cycloid reducer selection instructions: 1, due to the cycloid reducer for the fixed torque design, do the selection of the actual torque should be less than the machine rated torque maximum instantaneous load or starting load should be less than 160 of the machine rated load. 2. If the input shaft speed changes 1, it should be selected according to the conditions of use. If the required power is certain, it should be selected according to the power required for the lowest speed. If the required torque is certain, it should be selected according to the power required at high speed. 3. In addition, the working condition coefficient and power loss should be considered, and the working torque (or power) should be multiplied by the above condition coefficient K. 4, in the case of possible overload phenomenon, overload protection device should be installed. In order to prevent the reducer and its various motive power due to the transmission of large ring damage.