Min.Order FOB Price

2 set 40.00-70.00 dollar / set

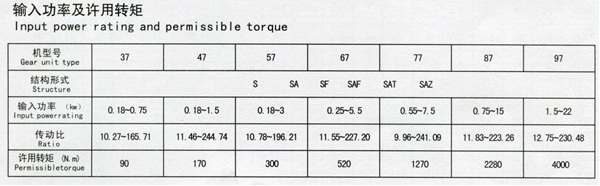

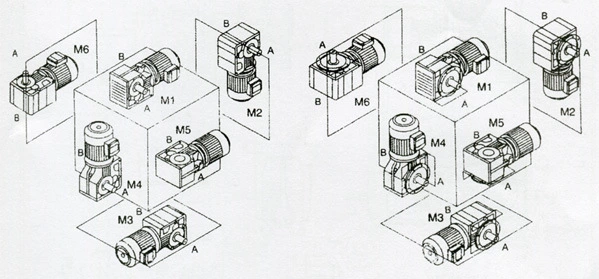

S series helical worm gear reducer is one of the four series reducer, because its input shaft and output shaft link mode is different from the other three products, irreplaceable; so in the reducer industry is very popular. Several helical gears and worms are organically combined inside the S series reducer. Power is provided by external motors and other equipment. The interaction between gears and worms or the use of external forces makes the reducer work in a balanced state. Minimizes the loss of the reducer, thereby prolonging the service life of the machine and increasing the safety and stability during use. S series helical gear reducer: can be foot type, flange type, shaft mounted installation, with input shaft or all kinds of motor direct connection, can be combined with the factory other reducer. With self-locking function. Power: 0.12 kW-30kW, reduction ratio: 7.5-14000. Maximum output torque: 6500N.m. S series helical gear-worm reducer introduction: A, small size, light weight, compact structure, strong carrying capacity B, smooth operation, small vibration, low noise, low temperature rise C, building block structure, easy combination, strong versatility. S series helical gear-worm reducer model is divided into: SF series reducer, SA series reducer, SAF series reducer, SAT series reducer, SAZ series reducer and other basic models. The speed ratio of the reducer ranges from 9.66 to 244.74; The torque range is from 43Nm to 4200Nm; The power can reach 22KW. In order to continuously produce and work normally, the reducer needs to be monitored and maintained regularly. After the reducer runs for a period of time, It is necessary to maintain the vent plug, drain plug and oil mark, and check the lubricating oil inside the reducer and the condition of some screws. S series hard tooth surface reducer model and marking description: S: indicates the type of reducer 37: indicates the base number Y: motor code 0.55-4P: indicates motor power and number of poles 32.40: Indicates transmission ratio M1: Mounting Form I: Location of motor junction box A: Output shaft or flange direction Structural form: common shaft extension type, shaft mounting type A, shaft extension flange type F, bearing flange type AF, bearing small flange type AZ, shaft mounting with anti-rotation arm AT, common shaft extension type, shaft input S, common shaft mounting type, shaft input AS, shaft extension flange type, shaft input FS, shaft mounting flange type, shaft input AFS Installation form: M1,M2,M3,M4,M5,M6