Min.Order FOB Price

2 set 40.00-100.00 dollar / set

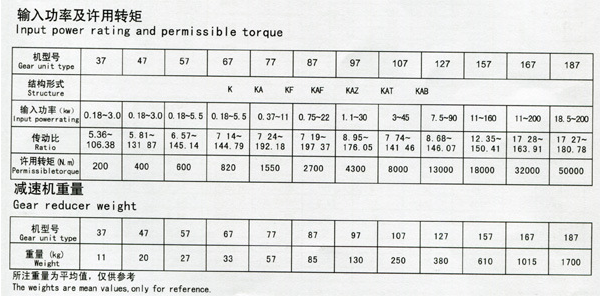

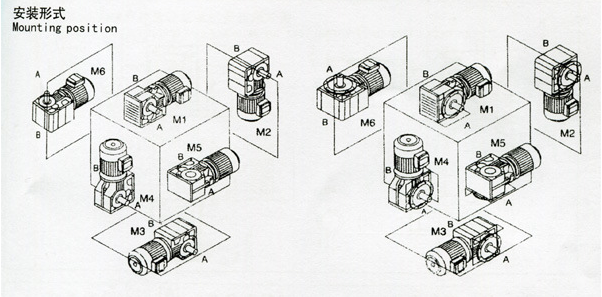

Compared with S series, K series hard tooth surface reducer has strong carrying capacity and pure gear transmission efficiency as high 96%. The maximum output power is 250kW, the maximum torque is 40000N.m, and the transmission ratio is 5.36-14526. Hard tooth surface reducer product introduction: Hard tooth surface reducer is sometimes called hard tooth surface reducer. Hard tooth surface reducer has the following design schemes: helical gear reduction motor installed on the foot, helical gear reduction motor installed on the flange, helical gear reduction motor installed on the foot flange, helical gear reduction motor installed on the flange with extended bearing box, single-stage helical gear reduction motor installed on the foot, and single-stage gear reduction motor installed on the flange. K series hard tooth surface reducer product features: K series hard tooth surface reducer space saving, reliable and durable, high overload capacity, power up to 200KW, low energy consumption, superior performance, deceleration efficiency up to 95%, small vibration, low noise, rigid cast iron box, gear surface by high frequency heat treatment, after precision machining, constitute a helical bevel gear. K series hard tooth surface reducer structure: K-shaft extension type, foot installation KA-Shaft-mounted coupling KF-Axial extension, flange mounting KAF-shaft mounted, flange mounted D-indicates axis input K series hard tooth surface reducer model and marking description: K: indicates the type of reducer 37: indicates the base number Y: motor code 0.55-4P: indicates motor power and number of poles 32.40: Indicates transmission ratio M1: Mounting Form I: Location of motor junction box A: Output shaft or flange direction Structural form: common shaft extension type, shaft mounting type A, shaft extension flange type F, bearing flange type AF, bearing small flange type AZ, shaft mounting with anti-rotation arm AT, common shaft extension type, shaft input S, common shaft mounting type, shaft input AS, shaft extension flange type, shaft input FS, shaft mounting flange type, shaft input AFS Installation form: M1,M2,M3,M4,M5,M6